|

Overview :

The

standard ignition modules and coils (not coil pack or electronically controlled

systems) fitted to many small Japanese engines aren't very wonderful. They are

better than points (hell, anything's better than points....) but they are pretty

marginal in terms of energy supplied to the spark plug. So what can be done

easily and cheaply?

If you have reluctor

style distributor (has a star shaped wheel that generates the timing pulses,

usually mounted right under the rotor button) the answer is surprisingly cheap

and relatively simple.

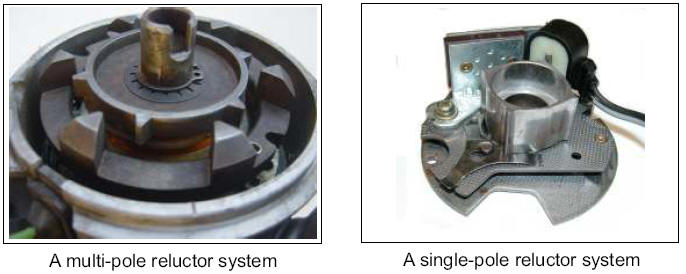

This upgrade will

work with either type of Variable Reluctance distributor pickups shown below. Hall

Effect systems will not be suitable for this particular modification.

You have

been WARNED!

However before you

race out and start chopping into your pride and joy, read the whole article and

have a careful look at your existing ignition system to ensure its essentially

as described. Due to the DIY nature of this description and variation car to car

there may be some challenges you have to overcome.

The article is a guide - not a guarantee! DTec accepts no responsibility should

you decide to undertake this modification - its entirely at your own risk.

What you need:

Looking at

the technical specifications, the old straight six cylinder Holden has the

highest output module and coil fitted to

readily available production cars. Go to a self serve wrecker, locate a suitable

donor vehicle, and on the distributor base will

be a cast flange with a sheet metal cover, under which will be a Bosch module -

the last three digits should be 021. It will

have four terminals.

Disconnect, unscrew

it and try NOT to wipe the white heatsink paste off the module base - it helps

with heat conduction to the

heatsink.

You will also need

the ignition coil as well as the mounting bracket and HT lead just to be safe.

It's an oil filled unit (the cylinder type) but if you want a more modern

looking, transformer coil then you need a Bosch HEC715 (female HT) or a HEC716

(male HT) They all perform similarly but the HEC715 / 16 won’t be common on

wrecks.

If you want to purchase new components see below for BOSCH part numbers.

Making the

modifications :

Using a

timing light, establish the standard timing at idle. In order to do this you may

need to refer to the manufacturers specifications to establish exactly under

what conditions the timing is determined.

Before you remove the distributor from your car, and very importantly - mark the

position of the rotor to the distributor body and the distributor body relative

to the engine - to make it easy to reinstall. Scribe a line, Texta mark etc -

but this is important - you WILL need it later.

Now for the "technical" stuff - there will be a pickup in the distributor body -

that is on the same plane as the reluctor (the star shaped wheel that rotates) -

with two wires from this to the ignition module.

If the ignition module is internal to the distributor, you need to cut these

wires and extend them with shielded cable (like audio cable - 2 cores and a

woven metal screen around them) to reach wherever your going to mount the new

module. The screen must to be grounded at one end only.

If your going to remove the pickup to make the installation easier, measure the

gap between the reluctor and the pickup coil. Sheets of paper / plastic etc will

work fine although brass feeler gauges are the correct tool.

Make certain you insulate the joins and ends well (heatshrink) and ensure the

new extended lead is clear of the rotating components of the distributor.

When selecting shielded cable, try and use a good quality silicone insulated

product. Its hot and unfriendly under the bonnet so a quality cable is a good

investment. Keep it away from all the hot engine bits and thermally shield if

necessary - fiberglass sleeving is ideal.

If the ignition module is already externally mounted then you may well be able

to use the existing trigger wiring. Check to see that the cable shield is

grounded at one end only - it is important.

The old module can be removed, or left – its your choice. If you removed the old

internal module, the new shielded cable may be able to exit through the existing

cable grommet making for a neat installation.

If you removed the

pickup from the distributor when cutting and extending the wires, then put it

back and set the gap between the reluctor and pickup coil to the same gap as

when it was removed and all should be well (you did measure it like we suggested

didn’t you.....) or if you have a factory service manual the gap will probably

be provided.

Under NO CIRCUMSTANCES should the two parts touch. If you didn’t measure the gap

before removal remember to allow for a little wobble in the shaft due to

mechanical tolerances and wear.

If the gap is too

large the engine will be difficult or impossible to start - too small and damage

will occur.

That's the distributor mods done.

Put the distributor back using the alignment marks – we told you they were

important ! Be careful not to damage the “O” ring or oil seal between the engine

and distributor body.

Mount the coil and

module - a small heatsink is required for the module - so make a 3mm thick

aluminium bracket about 70 x 50mm for the module and that will do. Do not run

the system without a suitable heatsink.

Mounting the module with the coil usually is easiest and in the same position as

the stock coil, as that gives you easy access to the original loom. A new or

recycled plug / socket will make the installation simpler and more professional.

If you wiped of the heatsink paste during removal of the module, electronic

component suppliers usually sell it. It is important to make good thermal

contact between the module and its new heatsink.

The Wiring :

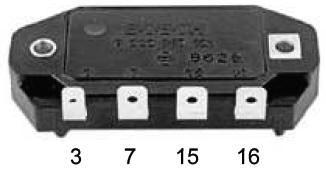

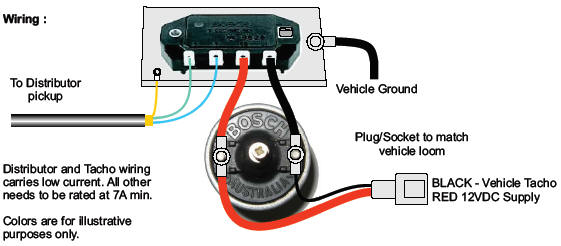

The

connections on the module are :

So.... ignition power

goes to the coil positive terminal and to module terminal 15, a ballast resistor

is NOT required. In fact a ballast wire or resistor will undo all your good

work! You can pick up power from the old coil positive connection on the loom

(not the old coil - just its loom connection).

Coil negative goes to module terminal 16, connect the new coils negative to the

old coils negative terminal on the loom so the ECU / tacho gets ignition pulses.

The shielded cable

that you have just installed goes to terminals 3 & 7 - don't make them permanent

just yet. Make sure the screen is grounded at one end as described previously.

Module shell is

connected to the vehicle ground via its bolted connection to the heatsink. Make

certain both the module AND heatsink have a good electrical ground connection.

“Star” or serrated washers may be used to assist.

The BIG

MOMENT :

That's

it... start the monster.

Get a timing light -

if you have to substantially rotate the distributor body to get the timing

right, then reverse the connections to terminals 3 & 7 and recheck.

This matters -

reverse connection might run but the dwell control in the module will operate

incorrectly and the rotor may no longer align with the internal posts / lead

connections molded into the distributor cap,

If you have an

Oscilloscope then you can verify the polarity manually. With the distributor

removed (remember to mark alignment as before) - rotate the distributor drive in

the normal direction of rotation and observe the pickup coils output waveform.

As the pole passes the coils projecting tooth the waveform should swing positive

first then go negative. You have now identified the trigger coils “+” and “-”

wires so connection to the module is straightforward.

Connecting a standard oscilloscope to the coil or module whilst the vehicle is running

is NOT recommended.

You now have a high performance, variable reluctance triggered, inductive

ignition system, powerful enough for most boosted installations let alone a

stock vehicle - more than a match for OE or aftermarket systems.

Total cost second hand - depends on wreckers but $20 is about it. New parts will

obviously cost more.

Do it

PROPERLY :

If your going to do

this - do it properly, nothings worse than poor wiring leading to breakdowns. If

your mystified by all this then DON'T ATTEMPT IT, its not that hard but some

basic electrical and mechanical knowledge is required.

The underlying Bosch module and coil are very reliable, so ensure you

workmanship is to the same standard.

BOSCH Part Numbers :

Number on Ignition

Module : 9222 067 021

Ignition Module as a retail boxed assembly : 9222 067 024 or BIM024

Ignition Coil - cylindrical oil filled : 9 220 061 445 (or other models as

specified for the “021” module)

Ignition Coil - transformer type : HEC015 (Female HT) or HEC016 (Male HT)

All we ask is that if you find the

information interesting then post a link on your site, It will encourage us to

continue publishing! Thanks.

◄ Back to

Tech Articles Page

◄ To Dyno

DIY System Page

|